As a driver, I always wonder how companies make the tires we enjoy using on our vehicles. So, how are tires made?

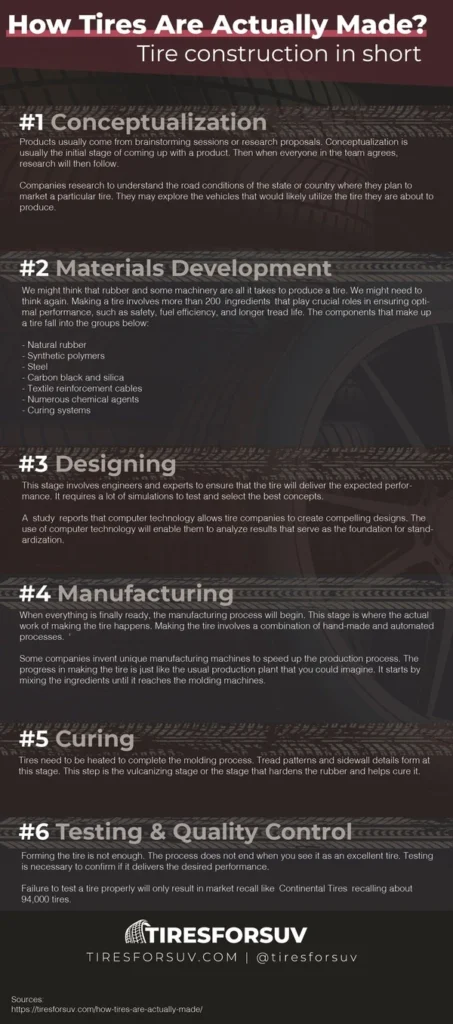

Making the tire is more than just molding rubber to the form of a tire. It involves researching, developing the materials, designing, manufacturing, curing, and testing or quality control. Tire production consists of many processes before it comes out to the market for us to use.

Let us take a look at the overview of every stage in making a tire.

The information you will find here is not as detailed as if you witness an actual tire-making process in tire plants and manufacturing facilities. However, it should be enough for you to understand the basic things involved in the tire-making process.

Conceptualization and Research Stage

Products usually come from brainstorming sessions or research proposals. Conceptualization is usually the initial stage of coming up with a product. Then when everyone in the team agrees, research will then follow.

Like any other product, companies conduct thorough research before starting their production of a particular tire. Companies study consumers’ tire usage and driving habits to ensure that their products match what users need.

Companies research to understand the road conditions of the state or country where they plan to market a particular tire. They may explore the vehicles that would likely utilize the tire they are about to produce.

Research is an essential stage in the process of making a tire. At this stage, a tire company decides on the feasibility of producing a new tire design.

Developing & Mixing the Materials

We might think that rubber and some machinery are all it takes to produce a tire. But, we might need to think again. Making a tire involves more than 200 ingredients that ensure optimal performance, such as safety, fuel efficiency, and longer tread life.

The components that make up a tire fall into the groups below:

- Natural rubber

- Synthetic polymers

- Steel

- Carbon black and silica

- Textile reinforcement cables

- Numerous chemical agents

- Curing systems

Natural Rubber

Natural rubber is the main component of the tread layers. It provides specific characteristics to tires to provide optimal performance.

Synthetic Polymers

Synthetic polymers are different types of rubber. They are butadiene and styrene-butadiene rubber. These rubber polymers mix with natural rubber to assist in the tire’s overall performance, such as rolling resistance, tread wear, and traction.

Steel

Tires feature steel wires such as belts, beads, or plies. The metal belts are placed under the tread to enhance the wear performance and handling.

Textile Reinforcement Cables

Textile reinforcement cables provide tire stability and help support the weight of your vehicle. They act as the primary reinforcing agent in the tire casing.

Carbon Black and Silica

These are fillers that reinforce the rubber. Their purpose is to help the tire resist tear, tensile strength, and abrasion.

Chemical Agents

A tire can get damaged when exposed to extreme temperature and oxygen – antioxidants help prevent it from happening.

Tires also include antiozonants to protect the tire against the effects of the ozone on the tire’s surface.

Curing Systems

These are usually sulfur and zinc oxide. These curing agents are crucial ingredients in making a tire as their role is to transform the rubber into a solid article during vulcanization or curing.

Designing Stage

This stage involves engineers and experts to ensure that the tire will deliver the expected performance. It requires a lot of simulations to test and select the best concepts.

Most tire companies now use computer-aided design methodology.

A study reports that computer technology allows tire companies to create compelling designs. The use of computer technology will enable them to analyze results that serve as the foundation for standardization.

Does the tire design matter? Of course, it does. The performance of a tire is directly reliant on its design. The tread design dictates the actual performance that the tire can provide.

Manufacturing Stage

When everything is finally ready, the manufacturing process will begin. This stage is where the actual work of making the tire happens. Making the tire involves a combination of hand-made and automated processes.

With the evolution of technology, the tire-making business is no longer as complicated and manual as a hundred years ago. Companies have research and development departments that continuously seek innovations to aid their manufacturing process.

Some companies invent unique manufacturing machines to speed up the production process. The progress in making the tire is just like the usual production plant that you could imagine. It starts by mixing the ingredients until it reaches the molding machines.

Curing Stage

Tires need to be heated to complete the molding process. Tread patterns and sidewall details form at this stage. This step is the vulcanizing stage or the stage that hardens the rubber and helps cure it.

Testing and Quality Control Stage

Forming the tire is not enough. The process does not end when you see it as an excellent tire. Testing is necessary to confirm if it delivers the desired performance.

Tire companies usually have their testing methods at their testing facility. Companies also conduct road tests to check for the tire’s actual road performance.

Failure to test a tire properly will only result in a market recall like Continental Tires recalling about 94,000 tires.

Conclusion

The process of making a tire is very intricate. It is more than just forming a round-shaped rubber to mount on the rims of our vehicles. It involves research, material selection, design conceptualization, testing, and quality control.

There are a lot of components of a tire. These components fall into several categories: natural rubber, synthetic polymer, steel belts, chemical agents, curing systems, etc.

Before companies release a particular tire to the market, they conduct proper testing to ensure safety. This testing phase also ensures that the tire can provide the projected performance.